The purchase of chassis cabinet matters needing attention

Release time:

Nov 01,2023

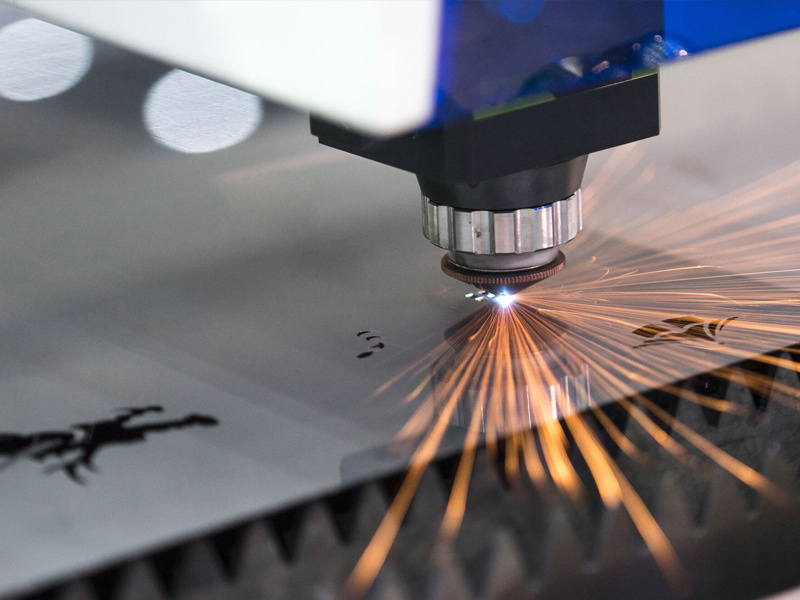

The chassis cabinet is a sheet metal processing chassis cabinet product. It is one of the indispensable equipment for various electronic devices and systems and intelligent control in various industries. It plays an important role in the overall work and operation. Therefore, the product quality and function of a chassis cabinet determine the user's purchase idea. Choose chassis cabinet products should pay attention to several aspects.

The chassis cabinet is a sheet metal processing chassis cabinet product. It is one of the indispensable equipment for various electronic devices and systems and intelligent control in various industries. It plays an important role in the overall work and operation. Therefore, the product quality and function of a chassis cabinet determine the user's purchase idea. Choose chassis cabinet products should pay attention to several aspects.

Price, under the premise of ensuring the quality and performance of the chassis cabinet, the lower price of the same type of chassis cabinet will obviously attract more buyers. Here we must carefully observe whether the material of the chassis cabinet is what we want, and whether the design and utilization of the internal space of the chassis cabinet meet our needs. It doesn't have to be expensive, it has to be better. We still want to be more specific to the object.

Quality issues. Good quality chassis cabinets can ensure long-term operation, while inferior chassis cabinets will have frequent problems. Frequent maintenance not only delays the use, but also increases the cost. Short service life is the fatal disadvantage of the chassis cabinet. The performance of the chassis cabinet will directly affect the normal working efficiency of the chassis cabinet. Efficient chassis cabinets will win more customer trust and support.

The use effect of the chassis cabinet is the standard to measure its quality. High-quality chassis cabinets bring convenience to users and enjoy the use of modern equipment. Low-quality chassis cabinets bring frequent maintenance, resulting in low work efficiency and increased costs. Therefore, when choosing the processing products of the chassis cabinet, we must consider many aspects, not just focus on the price.

Key words:

You Can Also Learn More About The Dynamics Of Tengyi.