Development Environment Faced by Chinese Sheet Metal Processing Equipment Enterprises

Release time:

Nov 01,2023

The environment mainly includes supply-side conditions, business environment, user development and human resources. The supply side is mainly materials and equipment. According to the current situation, materials are an eternal short board for us, and enterprises need to pay special attention to it. To have the concept of material market development, we should not only pay attention to the price, but also pay attention to the development trend of material application, especially to study the supply capacity and system changes of steel mills, so as to formulate a material procurement system suitable for the development of enterprises. It is very important to carry out research on the integration technology of materials and process, can save production costs, improve production efficiency.

The environment mainly includes supply-side conditions, business environment, user development and human resources. The supply side is mainly materials and equipment. According to the current situation, materials are an eternal short board for us, and enterprises need to pay special attention to it. To have the concept of material market development, we should not only pay attention to the price, but also pay attention to the development trend of material application, especially to study the supply capacity and system changes of steel mills, so as to formulate a material procurement system suitable for the development of enterprises. It is very important to carry out research on the integration technology of materials and process, can save production costs, improve production efficiency.

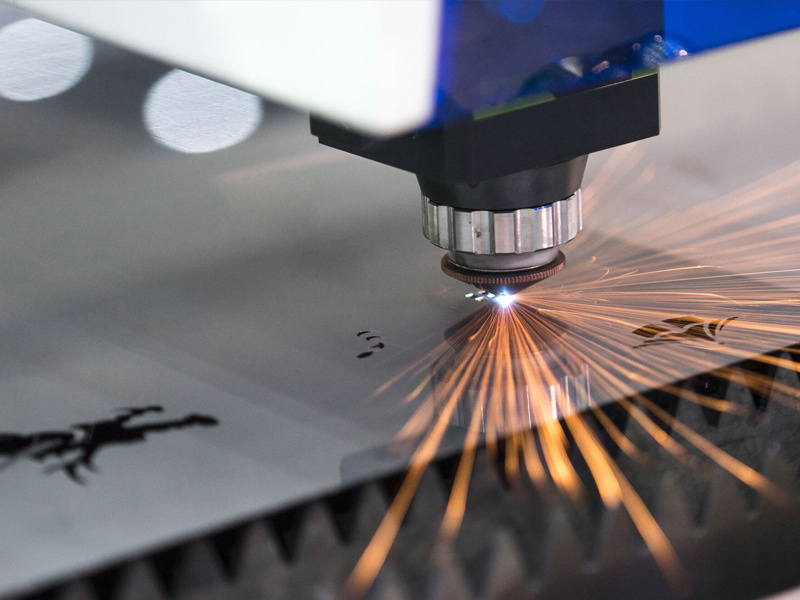

In terms of equipment, it is very important to be suitable for the present and to be forward-looking. To realize the progress of sheet metal processing, the equipment must have reliable and stable three capabilities, namely automation, digitization and informatization. At different stages of enterprise development, different capabilities of equipment are purchased for different products. On the other hand, compared with enterprises in other industries, domestic sheet metal processing enterprises have not formed the basic principle of enterprise workshop layout. The workshop design and layout are varied and disorganized. Most of the enterprise workshop layout does not meet or meet the needs of sheet metal processing technology. This requires domestic sheet metal processing enterprises to conduct necessary discussions and exchanges with equipment enterprises, and regard equipment suppliers as our "partners", to jointly promote the progress and development of sheet metal processing technology. At the same time, the workshop design and layout also need to attract the attention of the whole industry.

The business environment and human resources situation should be a concept of social management category, which are two issues that need to be considered when sheet metal processing enterprises invest in the establishment of enterprises. Once the project is implemented, it is also necessary to strengthen communication with relevant local government departments to create a good environment and human resources for enterprise development.

The user is not only our service object, but also a "mentor" who grows with us ". Growing up with excellent users is the concept that enterprises must adhere to. In the market of sheet metal processing products, enterprises should make a position for themselves and do something. Not all users are your God.

Here, I still want to talk about the famous "intelligence" problem. At present and in the future, "intelligence" is only an ideal. What we are doing at present is a production automation, digitization and informatization work, which is still far from the ideal "intelligence.

In the technological development of enterprises, automation should first be considered, especially "reliable" sheet metal automation. At present, enterprises must deeply understand the concept of digitalization, should gradually use digital tools, and should fully realize digitalization from the aspects of equipment control and process design, which is an important measure not to lag behind the times. Regarding informatization, China's sheet metal processing industry has just started, and there is still a lot of work to be done, especially the cognition and knowledge update of business managers or actual controllers are very important. There is no doubt that in the sheet metal manufacturing industry, we have lagged far behind the developed countries in the three aspects. How to do it, I have listed a lot of development needs before. In fact, the most critical point is that "enterprise managers and industry workers should have the responsibility of establishing industrial culture", starting from promoting in-depth cognition.

Key words:

You Can Also Learn More About The Dynamics Of Tengyi.